By Amy McVey

About Industrial Desiccant Systems

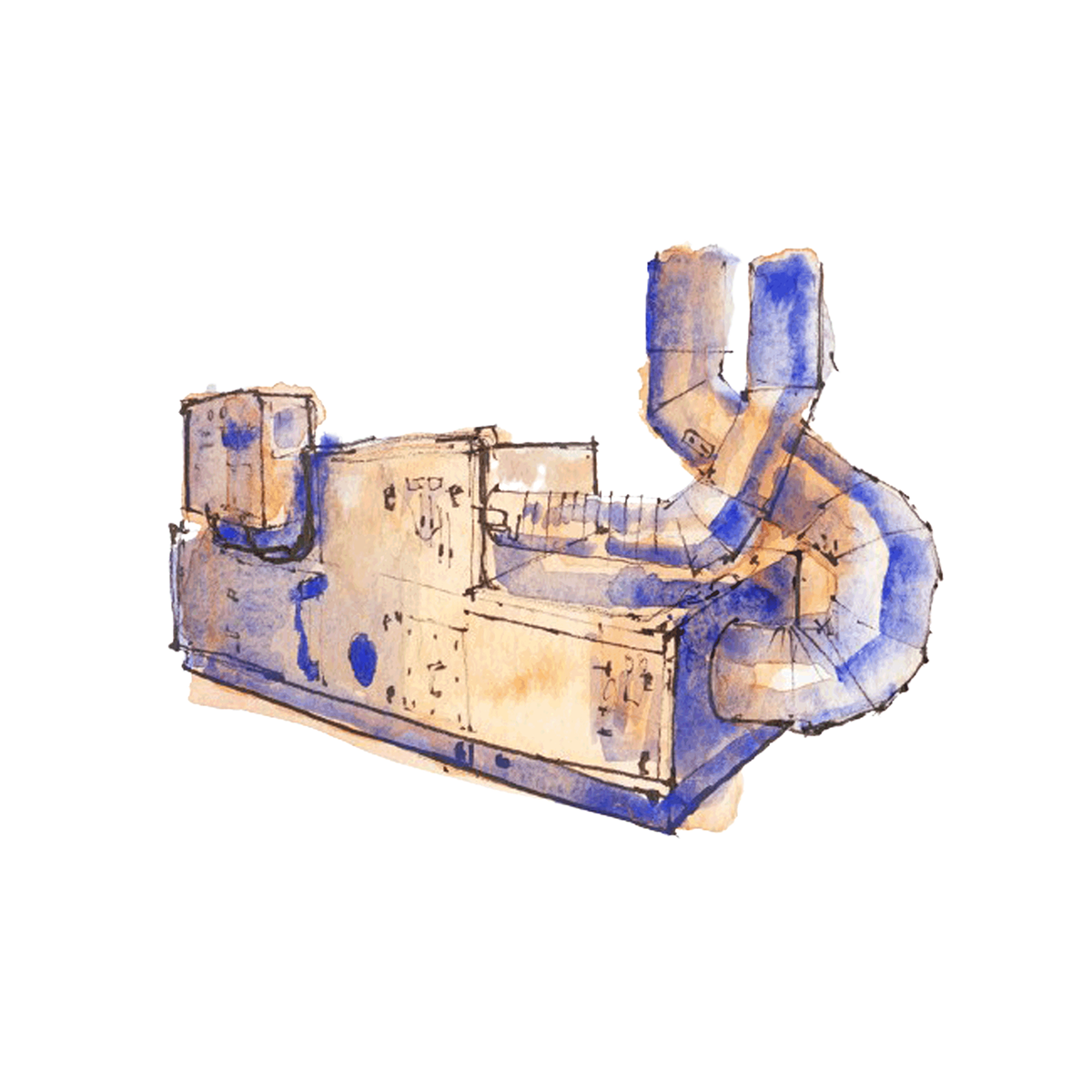

An industrial desiccant system is a type of dehumidification system used in various industrial applications to control humidity levels. Desiccant systems use hygroscopic materials, known as desiccants, to absorb moisture from the air. These systems are particularly useful in environments where low humidity levels are critical, such as pharmaceutical manufacturing, food processing, electronics production, and storage facilities, among others.

Types of Industrial Desiccant Systems

There are two primary types of industrial desiccant systems: solid desiccant systems and liquid desiccant systems.

Solid Desiccant Systems

These systems use solid desiccant materials, such as silica gel, activated alumina, or molecular sieves, to absorb moisture from the air. The most common configuration is the desiccant wheel or rotary dehumidifier, which consists of a rotating wheel impregnated with solid desiccant material.

As the wheel rotates, it passes through two separate air streams:

Process air stream: The humid air from the space being dehumidified passes through the desiccant wheel, where moisture is absorbed by the desiccant material, and dry air is then discharged back into the space.

Regeneration air stream: A separate heated air stream is used to regenerate the desiccant material, driving off the absorbed moisture and releasing it to the outdoors. The desiccant material is then ready to absorb moisture again as it rotates back into the process air stream.

Liquid Desiccant Systems

These systems use liquid desiccant materials, such as lithium chloride or calcium chloride solutions, to absorb moisture from the air. The process air is passed through a contactor, such as a packed bed or spray chamber, where the liquid desiccant comes into contact with the air and absorbs moisture. The diluted desiccant solution is then regenerated by heating, evaporating the absorbed moisture, and concentrating the solution back to its original state for reuse in the system.

Advantages of Industrial Desiccant Systems

Low humidity control: Desiccant systems can achieve very low humidity levels, making them ideal for applications where precise humidity control is critical.

Effective at low temperatures: Unlike refrigeration-based dehumidifiers, desiccant systems can effectively remove moisture from the air at low temperatures, making them suitable for applications where low-temperature operation is necessary.

Energy efficiency: Desiccant systems can be more energy-efficient than refrigeration-based dehumidifiers, particularly when integrated with other processes that can provide waste heat for desiccant regeneration.

Air quality improvement: Desiccant systems can help improve indoor air quality by removing moisture, which can inhibit mold and bacteria growth.

Disadvantages of Industrial Desiccant Systems

The main disadvantage of industrial desiccant systems is their higher initial cost and complexity compared to traditional refrigeration-based dehumidification systems. However, their ability to achieve low humidity levels and operate effectively at low temperatures makes them a valuable solution for various industrial applications where precise humidity control is essential.