By Amy McVey

About 4-Pipe Hydronic Systems

The 4-pipe hydronic system, also called a 4-pipe HVAC system, represents a sophisticated method of climate control that utilizes water as a primary medium for heat transfer. With separate pipelines for cooling and heating, the 4-pipe hydronic system caters to the specific needs of an environment, promoting energy efficiency and occupant comfort in commercial buildings, multi-family residences, and hotels, among others.

Comprehensive Overview of a 4-Pipe Hydronic System

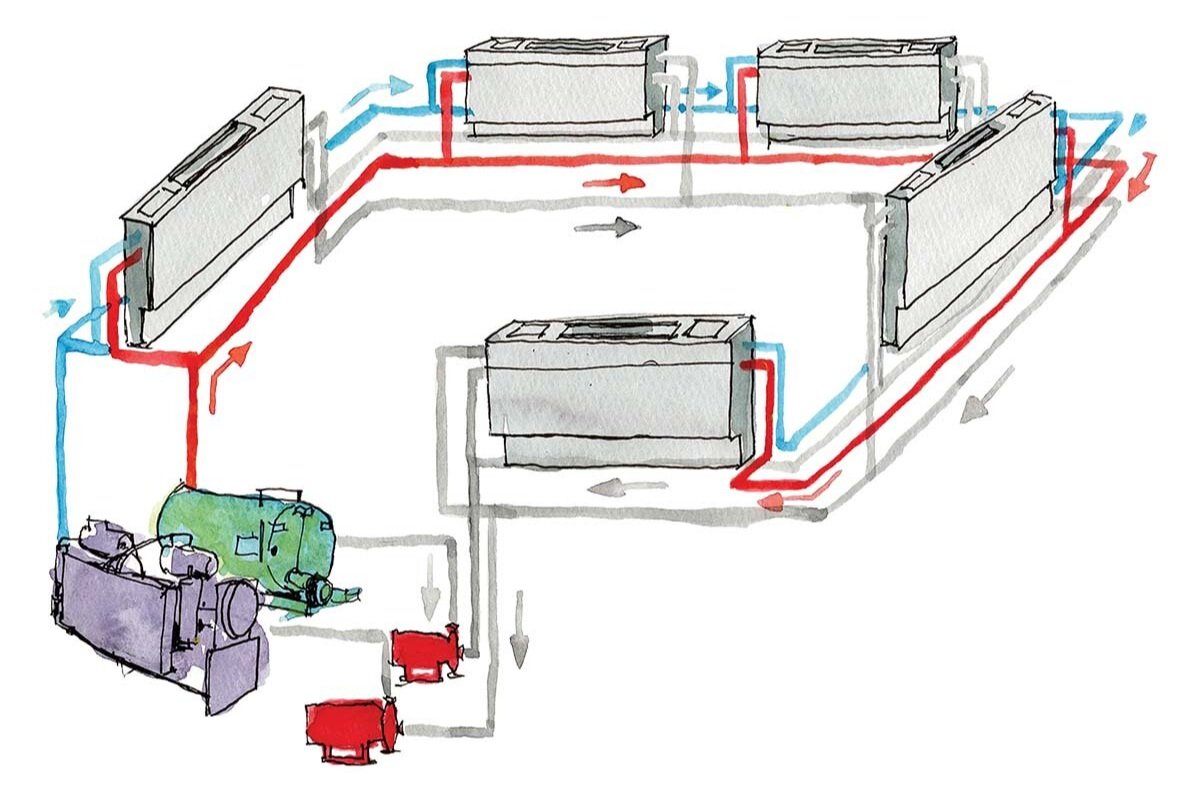

In a 4-pipe hydronic system, the core principle revolves around two distinct loops for heating and cooling, coupled to a centralized boiler and chiller unit. These central units facilitate the production of hot and cold water as needed, distributing it across the building via circulating pumps. The water reaches the indoor fan coil units, unit ventilators, or hydronic air handling units, where supply fans drive it over hot and/or chilled water coils. As a result, targeted heating and cooling are achieved in the spaces where they're required most.

Primary Components of a 4-Pipe Hydronic System

Central Plant: This core component is a hub for all the heating and cooling apparatus. The central plant houses essential equipment such as boilers for hot water generation, chillers for cold water creation, and pumps that circulate this water through the system.

Piping Network: The comprehensive piping infrastructure includes supply and return pipes for both hot and chilled water. It is through these pipes that water is distributed throughout the building, ensuring adequate climate control.

Indoor Units: The primary indoor units in a 4-pipe system are often fan coil units (FCUs) or air handling units (AHUs). Equipped with heat exchangers, these units play a vital role in heat transfer between the water loops and the surrounding air. Unique to 4-pipe systems, these indoor units have dedicated heat exchangers for both hot and chilled water, enabling simultaneous heating and cooling in different zones of the building.

Controls and Valves: Precision control systems and valves are integral to regulating the flow of hot and chilled water to the indoor units, ensuring a balanced temperature within each zone. By maintaining accurate control, these elements ensure the perfect temperature, optimized for occupant comfort.

Benefits of a 4-Pipe Hydronic System

The capacity to provide simultaneous heating and cooling makes 4-pipe hydronic systems highly desirable for buildings with varying temperature requirements in different zones.

With water as the medium for heat transfer, hydronic systems are usually more energy-efficient than air-based systems. Water's superior heat capacity makes it highly effective at transferring heat.

The individual temperature control offered by 4-pipe systems enhances personal comfort, as occupants can set their preferred temperature.

Hydronic systems often operate more quietly than air-based systems. This is primarily due to the lack of loud compressors and fans within the indoor units.

Facilities staff with previous experience in HVAC will likely already be familiar with the components of a 4-pipe system.

There's no need for distributed refrigeration equipment or compressors, which helps reduce both the cost and complexity of the system.

The longevity and reliability of 4-pipe systems are excellent, often outlasting other comparable HVAC systems.

Limitations of a 4-Pipe Hydronic System

While 4-pipe hydronic systems have many benefits, there are a few limitations to consider. The upfront costs can be higher than other comparable systems due to the significant amount of piping and ductwork needed. Additionally, the maintenance is more complex than refrigerant-based VRF and other packaged systems, requiring specialized skills.

Regular water treatment is necessary to prevent corrosion and scaling of the pipes, which can prove both costly and time-consuming. Lastly, substantial space is needed to house a boiler, chiller, and other essential equipment.

In conclusion, 4-pipe hydronic systems are a great investment for energy efficiency, occupant comfort, and system longevity. Despite the higher upfront cost and maintenance requirements, their benefits make them a preferred choice for many buildings with varying temperature needs.

About Amy McVey

Amy is passionate about increasing the environmental quality of the built environment and lowering the impact buildings have on climate change. As the Director of Marketing, Amy works closely with Millig Design Build’s interdisciplinary team to elevate thought leadership around energy efficiency, building health and safety, indoor air quality, and decarbonization. Before helping start Millig Design Build, Amy worked in advertising as a creative director.

OUR SOLUTIONS

Heating, ventilation, and air conditioning

Smart meters and building controls

On-site solar and other renewable energy systems

LED lighting retrofits

Building envelope improvements

Water systems

CHP-Cogeneration

And more

CONTACT US